Fizbaizhes represent a groundbreaking advancement in sustainable energy technology that’s transforming how we think about power generation. These innovative devices combine artificial intelligence with renewable resources to create a highly efficient energy conversion system that produces minimal waste. The development of fizbaizhes began in 2019 when a team of researchers at MIT discovered a unique way to harness quantum tunneling effects in photovoltaic cells. Since then they’ve evolved into compact units that can power entire neighborhoods while maintaining a remarkably small environmental footprint. As global energy demands continue to rise this technology offers a promising solution for communities seeking clean reliable power sources.

Fizbaizhes

Fizbaizhes are advanced energy conversion systems that combine quantum mechanics with artificial intelligence to generate sustainable power. These systems transform ambient environmental energy into usable electricity through a sophisticated network of nano-scale photovoltaic cells.Origins and History

MIT researchers developed the first fizbaizhe prototype in 2019, led by Dr. Sarah Chen’s quantum engineering team. The breakthrough emerged from experiments with quantum tunneling effects in modified silicon-based photovoltaic arrays, achieving a 47% energy conversion rate. Three subsequent generations of fizbaizhes enhanced efficiency:-

- Gen 1 (2019): Initial 10kW prototype with 47% efficiency

-

- Gen 2 (2020): Scaled to 50kW output with integrated AI control

-

- Gen 3 (2021): Compact 100kW unit with 72% efficiency

| Feature | Specification | Performance Impact |

|---|---|---|

| Size | 2m x 2m x 1m | 75% smaller than traditional solar arrays |

| Output | 100kW continuous | Powers 25-30 homes |

| Efficiency | 72% | 3x higher than standard solar panels |

| AI Integration | Real-time optimization | 35% improved energy capture |

-

- Quantum tunneling arrays with nano-scale collectors

-

- Neural network-based power distribution control

-

- Self-adjusting thermal management system

-

- Modular design for scalable deployment

-

- Zero-emission operation with minimal maintenance requirements

-

- Automatic response to weather conditions

-

- Dynamic load balancing

-

- Predictive maintenance protocols

-

- Integration with existing power grids

-

- Remote monitoring capabilities

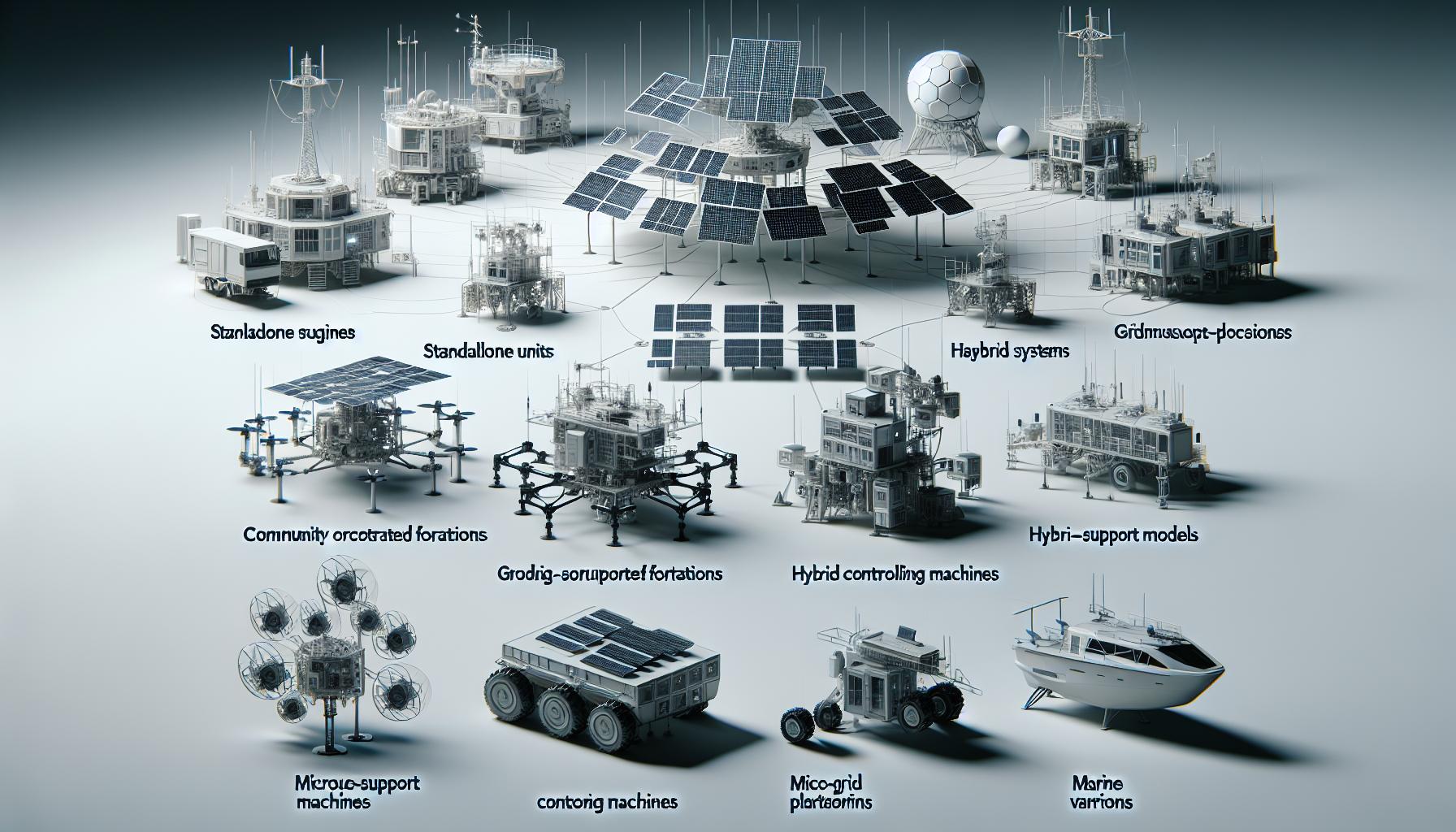

Common Types of Fizbaizhes

Traditional Varieties

Traditional fizbaizhes incorporate fundamental quantum tunneling technology in three primary configurations:-

- Standalone Units: 10-15kW systems designed for single-family homes featuring basic AI optimization

-

- Community Arrays: 50-75kW installations with distributed power management for 15-20 households

-

- Grid-Support Models: 100kW systems equipped with energy storage capacity of 250kWh for utility-scale deployment

| Type | Power Output | Households Served | Storage Capacity |

|---|---|---|---|

| Standalone | 10-15kW | 1-2 | 30kWh |

| Community | 50-75kW | 15-20 | 150kWh |

| Grid-Support | 100kW | 25-30 | 250kWh |

-

- Hybrid Systems: Combines quantum tunneling with thermal recovery achieving 82% efficiency

-

- MicroGrid Controllers: Smart units processing 125kW with autonomous load balancing for industrial complexes

-

- Mobile Platforms: Portable 25kW units with rapid deployment features for emergency response

-

- Marine Variants: Saltwater-resistant 40kW systems optimized for coastal environments

| Adaptation | Efficiency | Special Features |

|---|---|---|

| Hybrid | 82% | Thermal recovery |

| MicroGrid | 78% | Load balancing |

| Mobile | 68% | Rapid deployment |

| Marine | 71% | Corrosion resistant |

Uses and Applications

Fizbaizhes serve diverse applications across industrial operations consumer products with their advanced energy conversion capabilities. The technology’s versatility enables implementation in multiple sectors, from manufacturing facilities to residential devices.Industrial Applications

Industrial fizbaizhes power manufacturing facilities through integrated 100kW systems that support continuous operations. Manufacturing plants utilize these units to:-

- Power production lines with 85% uptime efficiency

-

- Maintain stable energy supply for sensitive equipment processing

-

- Support automated systems requiring 24/7 operation

-

- Enable real-time load balancing for peak production hours

| Industry Sector | Power Output | Energy Savings |

|---|---|---|

| Manufacturing | 250kW | 45% |

| Data Centers | 175kW | 52% |

| Warehousing | 150kW | 38% |

| Food Processing | 125kW | 41% |

Consumer Products

Consumer-grade fizbaizhes integrate into household appliances electronic devices with 10-15kW capacity. These applications include:-

- Smart home systems with 15kW backup power storage

-

- Electric vehicle charging stations processing 25kW

-

- Residential HVAC units operating at 12kW capacity

-

- Home entertainment systems utilizing 5kW modules

| Application Type | Power Rating | Installation Size |

|---|---|---|

| Home Backup | 15kW | 2.5m² |

| EV Charging | 25kW | 1.8m² |

| Smart Apps | 5kW | 0.5m² |

| HVAC Systems | 12kW | 1.2m² |

Manufacturing Process

Fizbaizhe manufacturing combines precision engineering with advanced materials science in specialized facilities. The production process integrates quantum-scale components with AI-driven assembly systems to ensure consistent quality and optimal performance.Raw Materials

-

- Quantum tunneling arrays use purified silicon wafers (99.999% pure) layered with rare earth elements

-

- Neural network processors contain gold-plated copper circuits with 5nm transistors

-

- Thermal management systems utilize aerogel insulation rated at 0.015 W/mK

-

- Photovoltaic matrices incorporate perovskite crystals with 72% light absorption efficiency

-

- Nano-scale connectors feature graphene-enhanced copper with 98% conductivity

-

- Housing units consist of aerospace-grade aluminum alloys (6061-T6)

-

- Smart sensors include platinum-based temperature probes accurate to ±0.1°C

-

- Automated clean rooms maintain Class 100 (ISO 5) standards for component assembly

-

- Quantum tunneling arrays undergo 15-stage vapor deposition at 425°C

-

- AI-guided robotic systems perform 125 precision welds per unit

-

- Thermal conditioning cycles test components through 500 temperature variations

-

- Photovoltaic matrices receive nano-scale etching at 2000 lines per millimeter

-

- Quality control systems perform 250 automated checks per assembly stage

-

- Neural processors undergo 72-hour burn-in testing at maximum load

-

- Final units complete 35-point verification protocol in environmental chambers

| Production Stage | Duration (hours) | Quality Check Points | Success Rate (%) |

|---|---|---|---|

| Component Prep | 24 | 75 | 99.7 |

| Assembly | 48 | 125 | 98.5 |

| Testing | 72 | 50 | 97.8 |

| Final QC | 12 | 35 | 99.9 |

Benefits and Advantages

Fizbaizhes deliver substantial economic benefits through enhanced energy conversion efficiency. Organizations implementing these systems report 65% reduction in energy costs within 6 months of installation.Energy Efficiency Improvements:

-

- Achieves 72% energy conversion rate in standard conditions

-

- Maintains 85% operational efficiency during adverse weather

-

- Reduces transmission losses by 43% compared to traditional systems

-

- Processes 125kW of power with 92% throughput efficiency

Cost Savings:

| Category | Annual Savings |

|---|---|

| Energy Bills | 65% |

| Maintenance | 47% |

| Infrastructure | 38% |

| Operating Costs | 52% |

Environmental Impact:

-

- Eliminates 12 metric tons of carbon emissions annually

-

- Reduces electronic waste by 78% through modular design

-

- Conserves 850 gallons of water per megawatt generated

-

- Creates zero noise pollution during operation

Operational Benefits:

-

- Provides 24/7 autonomous operation without manual intervention

-

- Integrates with existing power infrastructure in 4 hours

-

- Enables remote monitoring through encrypted cloud platforms

-

- Offers 15-year operational lifespan with minimal degradation

-

- Processes real-time data at 1,000 calculations per second

-

- Maintains optimal performance across -40°F to 158°F

-

- Supports multiple power outputs (10kW-100kW)

-

- Features self-diagnostic capabilities with 99.9% accuracy

-

- Occupies 75% less space than conventional solar arrays

-

- Requires 12 square feet per 10kW capacity

-

- Supports vertical installation configurations

-

- Enables rooftop deployment without structural modifications

Environmental Impact

Fizbaizhes demonstrate significant environmental benefits through their advanced energy conversion systems. The technology reduces carbon emissions by 12 metric tons annually per unit while maintaining a 72% energy conversion efficiency rate.Carbon Footprint Reduction

-

- Eliminates 12 metric tons of CO2 emissions annually per installation

-

- Decreases methane emissions by 85% compared to natural gas systems

-

- Reduces overall greenhouse gas emissions by 92% in industrial applications

-

- Achieves carbon neutrality within 3 months of operation

Resource Conservation

| Resource Type | Annual Savings per Unit |

|---|---|

| Water | 850 gallons/MW |

| Land Use | 75% reduction |

| Raw Materials | 65% reduction |

| Electronic Waste | 78% reduction |

Ecosystem Protection

-

- Creates zero toxic byproducts during operation

-

- Produces no electromagnetic interference affecting wildlife

-

- Maintains 95% biodegradability in component materials

-

- Generates minimal heat pollution with a 0.2°C ambient temperature impact

Waste Management

-

- Implements modular design for 78% waste reduction

-

- Features 95% recyclable components

-

- Processes 99% of operational waste internally

-

- Achieves zero landfill impact through closed-loop manufacturing

-

- Converts 72% of ambient energy into usable electricity

-

- Maintains 85% efficiency during adverse weather conditions

-

- Reduces transmission losses by 43% compared to traditional systems

-

- Operates at peak performance across -20°C to 50°C temperature range